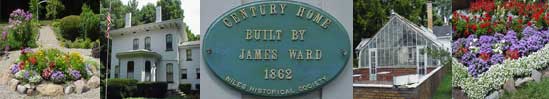

Ward-Thomas Museum

Thomas Steel Mills

Ward — Thomas

Museum

Home of the Niles Historical Society

503 Brown Street Niles, Ohio 44446

Click here to become a Niles Historical Society Member or to renew your membership

Click on any photograph to view a larger image, click on image again to zoom into photograph.

|

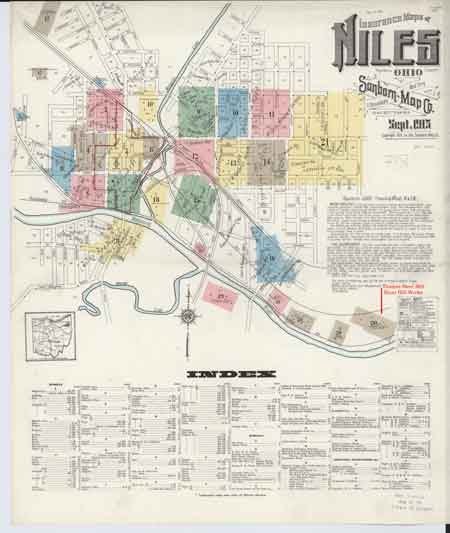

1915 Sanborn fire map of Niles. 1909 Sandborn fire map close-up. |

Thomas

Steel Mills. The Mahoning Valley Steel Company was formally organized on July 12, 1916, with a capital investment of $600,000. The original officers were Jacob D. Waddell, president; T. E. Thomas, vice president and treasurer; W. Aubrey Thomas, secretary; directors, John M. Thomas and M. T. Clingan and the officers named above. An interesting family dynamic was that Jacob D. Waddel married Mary Ann Thomas in December 12, 1917, making him the brother-in-law to the other directors, all children of John Rhys Thomas. The company erected a sheet mill plant at Niles, Ohio with an annual capacity of 48,000 tons of black steel sheets, and made improvements and extensions which permitted of the production of 12,000 tons of galvanized sheets per year. The plant employed approximately 425 men, and had an annual payroll of about $960,000. Offices were maintained at Niles, New York City, Chicago, West Hamilton (Ontario), and St. Louis. This company began a comprehensive housing plan, and invested by 1921 about $50,000 in this way, and would extend its housing operations as needed. It isn't figurative speech to say the steel mills created neighborhoods and cities. It's actually quite literal. Steel companies had real estate subsidiaries that built homes for employees, and in the case of McDonald, Ohio (Near Niles), US Steel built the entire town, including its city hall, fire/police station and parks. Just after World War II, there was a serious

shortage of steel. General Electric needed access for steel for

its growing electric supply division. Mahoning Valley Steel was

a hand rolling mill, also called a back and forth mill, which

did not make the type of steel needed by GE, but the mill did

have access to its quota of steel, which GE did need. The president

at that time, John P. Hosack, made a deal to sell the

company to GE if they agreed to build an Electrical conduit plant

on the site, which maintained jobs in Niles. General Electric

was forced to divest the supply company in 2006, and the plant

was closed by the new owner. |

|

|

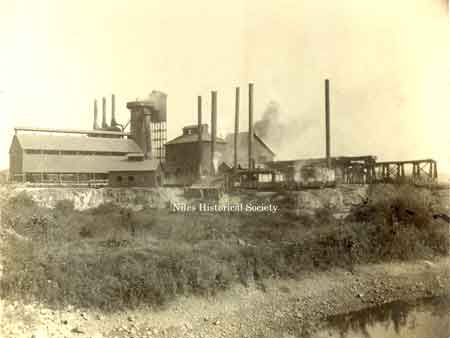

Thomas Steel mill located east of Mosquito Creek. |

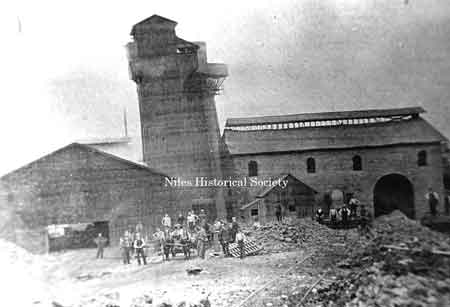

Thomas Steel Mill was a new rolling mill established by W. A. Thomas in 1902. It was located on Walnut Street and Summit Street. It was dismantled during the 1930 depression. PO1.628 |

This photograph represents enlargements made by John R. Thomas after acquiring property from Ward's in 1879. Sold by the Thomas' to Carnegie Steel Co. in 1900 which further enlarged the property. PO1.630 |

|

Built in 1870 by William Ward and known as the Wm. Ward & Co blast Furnace, it failed in the Panic of 1873. It was purchased by John R. Thomas in 1879 who increased capacity from 25 to 320 tons. In 1900 it became part of the Carnegie Steel Co. but was operated only in times of great demand for steel, the last period of steady use being WWI. Closed in 1920, dismantled in 1925. This picture shows the original Ward Blast Furnace. PO1.634 |

This picture shows the original Ward Blast Furnace in a different view. PO1.635 |

Carnegie Steel expanded the Thomas Steel Mill which was later dismantled in 1925. |

| |

||

|

Carnegie Steel expanded the Thomas Steel Mill which was later dismantled in 1925. |

The old Thomas Mill, known as Mill #8, was staffed with the crew taken in 1909, according to Clarence Glay, nephew of Albert Glay. The plant, he said, was located on Summit Street where Albee Homes were manufactured ans later occupied by Summit Supply Company. According the the History of Niles book, the Thomas furnace, 'out of blast' for two years, was 'blown in' prior to January 1, 1886. Industrial Expansion in Niles from 1912-1928

lists the Thomas Mill, owned by W.A. Thomas and C.S.

Thomas, at $2,000,000. The mill was considered one of the

twelve important firms incorporated in Niles. |

|

|

|

||